Hexagon Head Cap Screws

1.ISO 4018 Hexagon Head Screws

2.Own a factory. Eliminate the price difference of middlemen and enjoy price advantage.

3.Adopt top-quality thickened steel in the industry, ensuring high stability and long-lasting durability.

4.Support customer customization.

5. Provide professional sales and after-sales service. Welcome to inquire at any time.

6. Deliver on time.

Hexagon Head Cap Screws ISO 4018 are an important type of fastener. These screws are manufactured in accordance with the ISO 4018 standard. The hexagon head cap screw features a hexagonal head, which provides a convenient grip for installation and removal using tools. The screw is typically made of high-quality materials such as steel, ensuring strength and durability.Hexagon Head Cap Screws ISO 4018 are widely used in various industries and applications. They are commonly found in machinery, construction, automotive, and many other fields. The ISO 4018 specification ensures consistent quality and dimensional accuracy, making them reliable for a wide range of fastening needs. The hexagon head cap screw offers several advantages. Its design allows for secure fastening, preventing loosening under vibration or stress. The hexagonal head provides good torque transmission, enabling easy tightening to the required specification. In addition, these screws are available in different sizes and lengths to meet specific application requirements. They can be coated or treated to provide additional corrosion resistance or other desirable properties. Overall, Hexagon Head Cap Screws ISO 4018 are a reliable and versatile fastening solution that meets international standards and is widely trusted in the industrial world.

Pictures

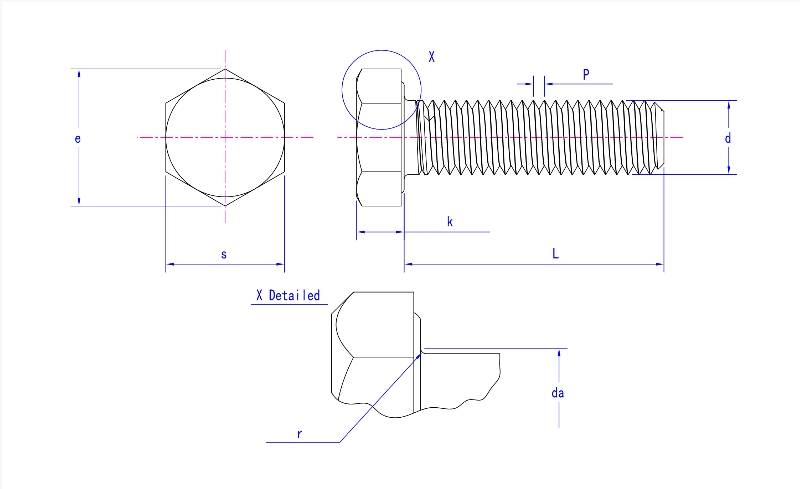

Product drawing

Product Specification

Size | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |

P | 0.8 | 1.0 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.0 | 2.5 | 2.5 | 2.5 | 3.0 | 3.0 | 3.5 | 3.5 | 4.0 | 4.0 | 4.5 | 4.5 | 5.0 | 5.0 | 5.5 | 5.5 | 6.0 | |

da max | 6.0 | 7.2 | 8.2 | 10.2 | 12.2 | 14.7 | 16.7 | 18.7 | 21.2 | 24.4 | 26.4 | 28.4 | 32.4 | 35.4 | 38.4 | 42.4 | 45.4 | 48.6 | 52.6 | 56.6 | 62.6 | 67.0 | 71.0 | 75.0 | |

e min | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |

k | max | 3.875 | 4.375 | 5.175 | 5.675 | 6.85 | 7.95 | 9.25 | 10.75 | 12.4 | 13.4 | 14.9 | 15.9 | 17.9 | 19.75 | 22.05 | 23.55 | 26.05 | 27.05 | 29.05 | 31.05 | 34.25 | 36.25 | 39.25 | 41.25 |

min | 3.125 | 3.625 | 4.425 | 4.925 | 5.95 | 7.05 | 8.35 | 9.25 | 10.6 | 11.6 | 13.1 | 14.1 | 16.1 | 17.65 | 19.95 | 21.45 | 23.95 | 24.95 | 26.95 | 28.95 | 31.75 | 33.75 | 36.75 | 38.75 | |

r min | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.5 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 | 2.0 | |

s | max | 8.0 | 10.0 | 11.0 | 13.0 | 16.00 | 18.00 | 21.0 | 24.0 | 27.0 | 30.0 | 34.0 | 36.0 | 41.0 | 46.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 | 85.0 | 90.0 | 95.0 |

min | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 | 26.16 | 29.16 | 33.0 | 35.0 | 40.0 | 45.0 | 49.0 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |

Support customer customization | |||||||||||||||||||||||||

Some introduction about our company

Certification

Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification through the scientific management of leaders of various departments and the pursuit of high quality for bolts and other fasteners. In addition, the laboratory owned by Star Company has obtained the certification in 2017. It passed the national CNAS certification in 2018, and the company passed the European CE certification in 2018.

Testing Equipment

Jinan Star Fastener Company attaches great importance to product quality and is equipped with complete quality inspection equipment, such as tensile testing machines, torque testers,metallographic microscopes, optical projectors, salt spray test chambers, coating thickness gauges, etc., which are used to test the tensile strength and elongation of fastener products and evaluate the mechanical properties of products. These equipment ensure that every link from raw materials to finished products can be strictly controlled in quality.

Production equipment

In order to meet the needs of different customers, the company has introduced a series of advanced production equipment, such as multi-station cold heading machines, thread rolling equipment, heat treatment equipment, shot blasting machines, sand blasting machines, electroplating lines and other surface treatment equipment, and fully automatic packaging equipment. These equipment not only improve production efficiency, but also ensure the consistency and stability of product quality.

Exhibition

Jinan Star actively participates in various exhibitions in the fastener industry. On the one hand, it expands its customer base, and on the other hand, it keeps up with the development trend of the fastener industry, understands customer needs, and then makes improvements in quality, service, etc.

Service

1. In the event of product quality issues, we offer a comprehensive return and exchange service for Hexagon Head Cap Screws ISO 4018. This service is designed to ensure that our customers are completely satisfied with the quality of the products they receive. If any quality problems are detected, customers can rely on our prompt and efficient return and exchange process to address the issue and obtain a replacement product that meets their expectations.

2. We are committed to providing extensive technical support and consultation on the installation and use of Hexagon Head Cap Screws ISO 4018. Our team of experienced professionals is available to answer any questions and provide detailed guidance on proper installation techniques, torque requirements, and usage precautions. Whether you are a professional installer or a DIY enthusiast, our technical support and consultation services will help you ensure the safe and effective use of these screws.

3. We offer valuable Hexagon Head Cap Screws ISO 4018 selection suggestions to ensure the perfect matching of screws and connectors. Our experts take into account various factors such as the application environment, load requirements, and material compatibility to recommend the most suitable screw size, thread pitch, and material for your specific needs. By following our selection suggestions, you can enhance the reliability and performance of your connections and avoid potential problems.

4. We provide a detailed interpretation of the ISO 4018 standard to help customers gain a thorough understanding of the technical parameters and application scenarios of ISO 4018 fully threaded hexagonal head screws. Our in-depth analysis covers aspects such as dimensional tolerances, mechanical properties, surface finishes, and marking requirements. By understanding the standard, customers can make informed decisions when selecting and using these screws, ensuring compliance with industry regulations and achieving optimal results.

Submitted successfully

We will contact you as soon as possible