DIN 7991 Hexagon Socket Countersunk Head Screws

Product: DIN 7991 Hexagon Socket Countersunk Head Screws

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

DIN 7991 hexagon socket countersunk screw is a specific fastener. The head of the hexagon socket countersunk screw is conical with a recessed hexagon in the middle. After installation, the head of the screw can be embedded in the mounting surface, making the surface smooth and beautiful. Due to this design, the head of the countersunk hexagon socket screw can be embedded in the component, a large torque can be applied, and the connection strength is high.

Pictures

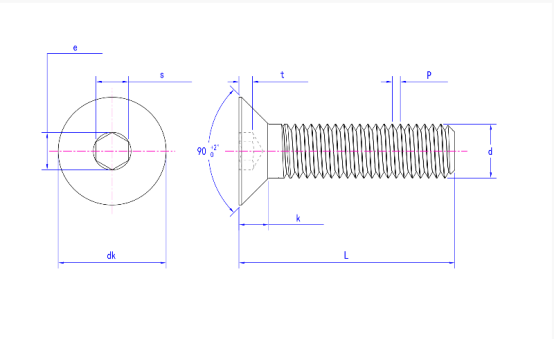

Product drawing

Product Specification

Size | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | |

P | 0.5 | 0.7 | 0.8 | 1.00 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.50 | 2.50 | 2.5 | 3 | |

dk | max | 6.00 | 8.00 | 10 | 12.00 | 16.00 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

e min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 16 | 16 | 16 | |

k max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7.00 | 7.5 | 8.5 | 13.1 | 13.1 | 14 | |

s | min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 14.032 | 14.032 | 14.032 |

max | 2.1 | 2.60 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.121 | 14.212 | 14.212 | 14.212 | |

t | max | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 8.8 | 8.8 | 10.3 |

min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5.00 | 5.2 | 8.44 | 8.44 | 9.87 | |

Support customer customization | ||||||||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

FAQ

1.What are the materials and performance grades of DIN 7991 hexagon socket screws?

The DIN 7991 hexagon socket countersunk screws we provide are made of high-quality materials. These materials have high strength, corrosion resistance and other characteristics, which can ensure that the screws can maintain good performance in various environments.

We provide a variety of performance grades to meet the needs of different customers. The choice of performance grade mainly depends on factors such as the load borne by the screw, the working environment and the installation requirements.

2.About the specifications and sizes of screws?

Customers can choose the appropriate specifications and sizes according to specific application requirements. We will provide detailed technical parameters and drawings for customers' reference.

3.About the installation and use of screws?

The installation and use of hexagon socket countersunk screws are relatively simple, but some details need to be paid attention to. For example, before installation, it is necessary to clean the threaded connection surface to ensure that there are no impurities and oil stains; during the installation process, it is necessary to apply appropriate torque to avoid over-tightening or over-loosening; when disassembling, it is necessary to use appropriate tools to avoid damage to screws and connectors.

We will provide detailed installation and use instructions, and provide technical support and consulting services to customers to ensure that customers can use the screws correctly and achieve the expected connection effect.

Submitted successfully

We will contact you as soon as possible