ASME/ANSI B18.3.1M-1 Socket Head Cap Screws

Product: ASME/ANSI B18.3.1M-1 Socket Head Cap Screws

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

The ASME/ANSI B18.3.1M-1 standard covers metric hex socket head screws. ASME/ANSI B18.3.1M-1 metric hex socket head screws come in specific designs and sizes and are commonly used in various engineering and mechanical applications. ASME/ANSI B18.3.1M-1 metric hexagon socket head screws are characterized by their head design, which has a cylindrical top and a hexagonal socket for turning and tightening using an allen wrench or screwdriver. This design provides higher torque transfer capabilities and better anti-skid performance.

Pictures

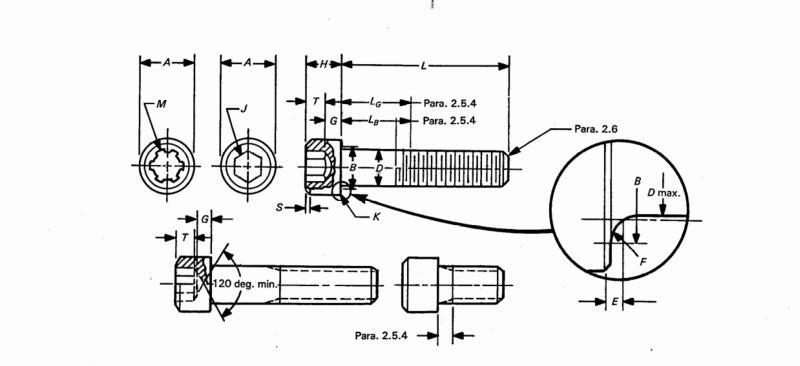

Product drawing

Product Specification

Size | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | |

P | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | |

D | max | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 |

min | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | |

A | max | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 |

min | 2.87 | 3.65 | 4.33 | 5.32 | 6.8 | 8.27 | 9.74 | 12.7 | 15.67 | |

J | nom. | 1.5 | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 | 5.0 | 6.0 | 8.0 |

E | max | 0.34 | 0.51 | 0.60 | 0.68 | 1.02 | ||||

F | min | 0.1 | 0.2 | 0.25 | 0.4 | 0.4 | ||||

H | max | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 |

min | 1.52 | 1.91 | 2.4 | 2.89 | 3.88 | 4.86 | 5.85 | 7.83 | 9.81 | |

S | max | 0.16 | 0.20 | 0.25 | 0.30 | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 |

B | max | 2.0 | 2.6 | 3.1 | 3.6 | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 |

min | 1.8 | 2.2 | 2.7 | 3.2 | 4.4 | 5.4 | 6.5 | 8.8 | 10.8 | |

K | max | 0.08 | 0.13 | 0.20 | ||||||

Support customer customization | ||||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Service

1. Provide cylinder head screws that comply with ASME/ANSI B18.3.1M-1 standards.

2. Produce non-standard specifications of cylinder head screws according to customers' specific needs.

3. Provide technical guidance on the selection, installation and maintenance of ASME/ANSI B18.3.1M-1 cylinder head screws.

4. If there is a problem when using ASME/ANSI B18.3.1M-1 cylinder head screw products, we provide timely after-sales service and solutions.

FAQ

1. How to choose the appropriate ASME/ANSI B18.3.1M-1 cylinder head screw?

When selecting ASME/ANSI B18.3.1M-1 cylinder head screws, consider the application environment, load and other factors. Our technical staff can assist you in selecting the appropriate ASME/ANSI B18.3.1M-1 cylinder head screw specifications and materials based on your specific application needs.

2. Is there an updated version of the ASME/ANSI B18.3.1M-1 standard?

Yes, the ASME/ANSI B18.3.1M standard may be updated over time. We will pay close attention to the latest developments in standards and provide customers with products that comply with the latest standards. At the same time, we will also provide information and explanations about the new standards to help customers better understand and apply the new standards.

3. What impact does the material of the screw have on performance?

The material of the screw directly affects its strength, corrosion resistance, wear resistance and other properties.

Submitted successfully

We will contact you as soon as possible