Hexagon Head Screw DIN 933

1.DIN 933 Fully Threaded Hexagon Head Bolt

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Fully Threaded Hexagon Head Screw DIN 933 are a commonly employed fastener. The DIN 933 standard is applicable to thread diameters ranging from M1.6 to M52. The fully threaded design enables the bolt to be securely locked on the part and offers excellent anti-loosening characteristics. Simultaneously, since the entire bolt is threaded, it effectively guarantees the stability of the fastened connection. This design also enables the bolt to better distribute forces when under load, enhancing its overall strength and durability. The Fully Threaded Hexagon Head Screw DIN 933 stipulates the material, hardness, tensile strength, and other mechanical properties of bolts, as well as heat treatment requirements to meet diverse environmental and application requirements.

Pictures

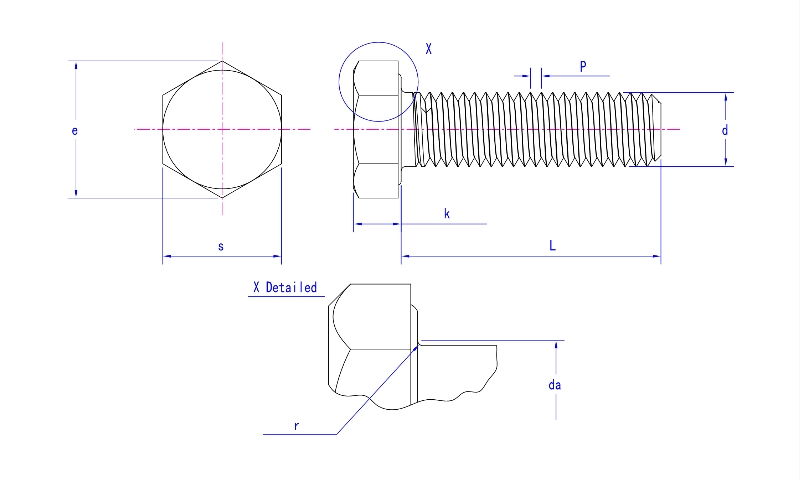

Product drawing

Product Specification

Size | M1.6 | M1.7 | M2 | M2.3 | M2.5 | M2.6 | M3 | M3.5 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | |

P | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.0 | 2.5 | 2.5 | 2.5 | 3.0 | 3.5 | 3.5 | 4.0 | 4.0 | 4.5 | 4.5 | 5.0 | 5.0 | |||||

da max | 2.0 | 2.1 | 2.6 | 2.9 | 3.1 | 3.2 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | |

e min | 3.41 | 3.82 | 4.32 | 4.95 | 5.45 | 5.51 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | 30.14 | 33.53 | 35.72 | 39.98 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | |

k | min | 0.98 | 1.33 | 1.28 | 1.73 | 1.58 | 1.93 | 1.88 | 2.28 | 2.68 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | 11.28 | 12.28 | 13.78 | 14.78 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 |

max | 1.22 | 1.08 | 1.52 | 1.48 | 1.82 | 1.68 | 2.12 | 2.52 | 2.92 | 3.65 | 4.15 | 4.95 | 5.45 | 6.56 | 7.68 | 8.98 | 10.18 | 11.72 | 12.72 | 14.22 | 15.22 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | |

r min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.6 | 1.6 | |

s | max | 3.2 | 3.5 | 4.0 | 4.5 | 5.0 | 5.0 | 5.5 | 6.0 | 7.0 | 8.0 | 10.0 | 11.0 | 13.0 | 17.0 | 19.0 | 22.0 | 24.0 | 27.0 | 30.0 | 32.0 | 36.0 | 41.0 | 46.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 |

min | 3.02 | 3.32 | 3.82 | 4.32 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | 26.67 | 29.67 | 31.61 | 35.38 | 40.0 | 45.0 | 49.0 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | ||

Support customer customization | |||||||||||||||||||||||||||||||

Some introduction about our company

Certification

Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification through the scientific management of leaders of various departments and the pursuit of high quality for bolts and other fasteners. In addition, the laboratory owned by Star Company has obtained the certification in 2017. It passed the national CNAS certification in 2018, and the company passed the European CE certification in 2018.

Workshop

The workshop of Jinan Star Fastener Co., Ltd. is the core area of the company's production and manufacturing, with advanced production equipment. The reasonable layout of the workshop and the scientific production process ensure the efficient production and high-quality output of fastener products.

Testing Equipment

Jinan Star Fastener Company attaches great importance to product quality and is equipped with complete quality inspection equipment, such as tensile testing machines, torque testers,metallographic microscopes, optical projectors, salt spray test chambers, coating thickness gauges, etc., which are used to test the tensile strength and elongation of fastener products and evaluate the mechanical properties of products. These equipment ensure that every link from raw materials to finished products can be strictly controlled in quality.

Exhibition

Jinan Star actively participates in various exhibitions in the fastener industry. On the one hand, it expands its customer base, and on the other hand, it keeps up with the development trend of the fastener industry, understands customer needs, and then makes improvements in quality, service, etc.

Packing

Service

1. We possess a comprehensive inventory management system and offer inventory management services for in-stock fastener products to guarantee that we can supply the Fully Threaded Hexagon Head Screw DIN 933 you need promptly.

2. Regarding your order, we arrange Fully Threaded Hexagon Head Screw DIN 933 schedules rationally and have a professional follow-up team to inform you of the order processing progress and logistics information in real time.

3. If you are not entirely clear about the required Fully Threaded Hexagon Head Screw DIN 933 specifications and models, we can provide professional product consultation and selection suggestions based on your specific needs and application scenarios to assist customers in choosing the appropriate DIN 933 fully threaded hexagonal head bolt.

FAQ

1. What surface treatments are available for Fully Threaded Hexagon Head Screw DIN 933?

The surface treatment options for DIN 933 bolts typically comprise galvanization, phosphating, blackening, and others, aiming to enhance the corrosion resistance and appearance quality of the bolts. Customers can select the appropriate surface treatment method based on their specific requirements. 2. What precautions should be taken when installing and using Fully Threaded Hexagon Head Screw DIN 933? During the installation of Fully Threaded Hexagon Head Screw DIN 933, ensure that the bolts and nuts fit properly and avoid being overly tight or loose. At the same time, pay attention to the tightening torque of the bolts to prevent damage to the bolts due to excessive tightening. In special environments (such as high temperature, low temperature, corrosion, etc.), corresponding protective measures should be taken to guarantee the normal usage of bolts.

Submitted successfully

We will contact you as soon as possible