Double Ended Screws

1.DIN 938 Double-ended Bolts bm=1d

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Double Ended Screws DIN 938, that is, double-ended screws or stud bolts that meet the DIN 938 standard, have the following appearance characteristics: the screw has two identical threaded ends, moderate length, and the thread length at both ends is usually equal, about 1 times the diameter of the screw (i.e. 1d); headless design, usually called self-drilling screws or screws, directly connected by threads. Common surface treatments include zinc plating, chrome plating, nickel plating, black oxide treatment, hot-dip galvanizing (H.D.G.), etc. to improve its corrosion resistance and aesthetics. Depending on the material, Double Ended Screws DIN 938 has high tensile strength and yield strength and can withstand large external forces. After appropriate surface treatment, such as zinc plating or chrome plating, the corrosion resistance of the screw can be significantly improved and the service life can be extended. The double-end design allows the screw to be threaded at both ends, which is convenient for installation and removal. Double Ended Screws DIN 938 are widely used in machinery, construction engineering, and automotive fields due to their unique performance and appearance characteristics. Jinan Star provides customized services and can produce screws of different sizes, materials and surface treatments according to customer needs.

Pictures

Product drawing

Product Specification

Size | M3 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | |

bm | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 22.0 | 24.0 | 25.0 | 30.0 | 32.0 | 35.0 | 38.0 | 42.0 | 45.0 | 48.0 | 52.0 | |

b | a | 12 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | 102 | 110 |

b | 18 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | 102 | 108 | 116 | |

c | / | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | 115 | 121 | 129 | |

ds | max | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 22.0 | 24.0 | 27.0 | 30.0 | 33.0 | 36.0 | 39.0 | 42.0 | 45.0 | 48.0 | 52.0 |

min | 2.86 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 39.61 | 41.61 | 44.61 | 47.61 | 51.54 | |

x1(d) | 1.25 | 1.75 | 2.0 | 2.5 | 2.5 | 3.2 | 3.8 | 4.3 | 5.0 | 5.0 | 6.3 | 6.3 | 6.3 | 7.5 | 7.5 | 9.0 | 9.0 | 10.0 | 10.0 | 11.0 | 11.0 | 12.5 | 12.5 | |

x2(d) | 0.7 | 0.7 | 0.9 | 1.0 | 1.25 | 1.6 | 1.9 | 2.2 | 2.5 | 3.2 | 3.2 | 3.2 | 3.8 | 3.8 | 4.5 | 4.5 | 5.0 | 5.0 | 5.5 | 5.5 | 6.3 | 6.3 | ||

Some introduction about our company

Application

Jinan Star Company specializes in the production of fastener products. Our bolts, nuts and other products are widely used in machinery, railways, automobiles, construction, electrical, bridges, communications, firefighting and other industries.

Workshop

The workshop of Jinan Star Fastener Co., Ltd. is the core area of the company's production and manufacturing, with advanced production equipment. The reasonable layout of the workshop and the scientific production process ensure the efficient production and high-quality output of fastener products.

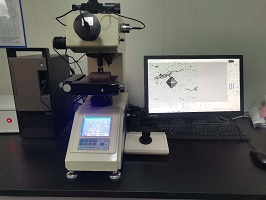

Testing Equipment

Jinan Star Fastener Company attaches great importance to product quality and is equipped with complete quality inspection equipment, such as tensile testing machines, torque testers,metallographic microscopes, optical projectors, salt spray test chambers, coating thickness gauges, etc., which are used to test the tensile strength and elongation of fastener products and evaluate the mechanical properties of products. These equipment ensure that every link from raw materials to finished products can be strictly controlled in quality.

Production equipment

In order to meet the needs of different customers, the company has introduced a series of advanced production equipment, such as multi-station cold heading machines, thread rolling equipment, heat treatment equipment, shot blasting machines, sand blasting machines, electroplating lines and other surface treatment equipment, and fully automatic packaging equipment. These equipment not only improve production efficiency, but also ensure the consistency and stability of product quality.

Exhibition

Jinan Star actively participates in various exhibitions in the fastener industry. On the one hand, it expands its customer base, and on the other hand, it keeps up with the development trend of the fastener industry, understands customer needs, and then makes improvements in quality, service, etc.

Service

1.Customize Double Ended Screws DIN 938 for different lengths, diameters, strength levels.

2. Answer customer questions on technical parameters, fields, usage of Double Ended Screws DIN 938.

3. Control quality production to meet DIN 938 standards and customer quality needs.

FAQ

1.What does b1=1d in Double Ended Screws DIN 938 bm=1d mean?

b1 in DIN 938 bm=1d represents a bolt size parameter equal to the thread diameter (d), providing stronger load-bearing capacity and stable connection.

2. In what situations are DDouble Ended Screws DIN 938 suitable?

Suitable for connecting non-detachable parts or where two-way tension is needed, like bridges, buildings, and mechanical equipment.

3. How to ensure the quality and performance of the Double Ended Screws DIN 938 product?

Answer: Use strict quality control from procurement to inspection to meet DIN 938 standards and customer needs.

4. Can the Double Ended Screws DIN 938 be customized as per my needs?

Yes, product customization available for length, diameter, strength grade, etc.

Submitted successfully

We will contact you as soon as possible